Machine for mining gold has come a long way in recent years, with advanced technology revolutionizing the industry. The incorporation of cutting-edge machine technology has significantly improved the efficiency and effectiveness of gold mining operations. This technological advancement has not only streamlined the process of extracting gold but has also made it more environmentally friendly. In this article, we will explore how advanced machine technology is revolutionizing the gold mining industry and the impact it is having on the sector as a whole.

Revolutionizing gold mining with advanced machine technology involves the use of state-of-the-art equipment and machinery to extract gold from the earth more efficiently and sustainably. This can include the implementation of automated systems, drones, and advanced monitoring technologies to increase productivity while minimizing environmental impact. Additionally, the use of advanced machine technology allows for more precise and targeted extraction, resulting in higher yields and reduced waste. Overall, the integration of advanced machine technology in gold mining has the potential to transform the industry and improve its sustainability and efficiency.

Revolutionizing Gold Mining with Advanced Machine Technology

In recent years, the gold mining industry has seen a significant shift towards the use of advanced machines to streamline operations and maximize efficiency. From autonomous haul trucks to remote-controlled drilling rigs, these technological innovations have revolutionized the way gold is extracted from the earth. With the help of cutting-edge equipment, mining companies are able to increase productivity, improve safety, and reduce environmental impact. As the industry continues to evolve, the integration of machine learning, robotics, and artificial intelligence is set to further transform the process of gold mining.

Revolutionizing gold mining with advanced machine technology involves implementing cutting-edge equipment and systems to improve efficiency, safety, and environmental impact. This includes utilizing advanced drills, crushers, and processing technology to extract and refine gold more effectively. Additionally, incorporating automation and digital technologies can optimize operations and minimize human error. Overall, embracing advanced machine technology in gold mining can significantly enhance productivity and sustainability in this industry.

Maximizing Efficiency: The Latest Innovations in Gold Mining Machinery

Maximizing Efficiency: The Latest Innovations in Gold Mining Machinery delves into the cutting-edge technologies and advancements in equipment used in gold mining operations. The article discusses how these innovations are helping mining companies optimize their processes and maximize their productivity. It also explores the impact of these advancements on safety, environmental sustainability, and cost-effectiveness in the gold mining industry. Additionally, it provides insights into the future direction of gold mining machinery, as well as the potential challenges and opportunities that lie ahead for the sector.

The Future of Gold Mining: Automation and Machine Learning

The future of gold mining is increasingly being shaped by automation and machine learning technologies. These advancements are revolutionizing the industry by improving productivity, efficiency, and safety.

Automation allows for the use of advanced machinery and robotics to perform tasks that were previously done manually, such as drilling, hauling, and processing ore. This not only speeds up operations but also reduces the risk of accidents and injuries for workers.

Machine learning is also playing a significant role in gold mining by enabling predictive maintenance, optimizing processes, and even discovering new mineral deposits. By analyzing large volumes of data, machine learning algorithms can identify patterns and trends that human operators might miss, leading to more informed decision-making and better outcomes.

Overall, automation and machine learning are expected to continue transforming the gold mining industry, increasing output, reducing costs, and minimizing environmental impact. As these technologies become more advanced and widespread, they will play a crucial role in shaping the future of gold mining.

Exploring the Potential of Robotics in Gold Mining Operations

Exploring the Potential of Robotics in Gold Mining Operations involves leveraging advanced technologies to improve efficiency, safety, and productivity. Robotics can be used for various tasks in gold mining, such as drilling, blasting, hauling, and ore processing. By employing robotics, mining companies can minimize the risk to human workers and access hard-to-reach or hazardous areas. Additionally, robotic systems can collect and analyze real-time data, leading to more informed decision-making and enhanced operational performance. The adoption of robotics in gold mining has the potential to revolutionize the industry by increasing output and reducing costs while ensuring sustainable and responsible mining practices.

Cutting-Edge Equipment for Sustainable Gold Mining Practices

Cutting-edge equipment for sustainable gold mining practices includes advanced machinery and technology designed to reduce environmental impact and improve efficiency. This can include automated sorting systems to separate gold from waste rock, as well as water recycling systems to minimize water usage and contamination. Additionally, advancements in drilling and extraction techniques can help minimize disturbance to the surrounding ecosystem. Overall, the use of cutting-edge equipment in sustainable gold mining practices is aimed at minimizing environmental harm while maximizing the yield of valuable resources.

Enhancing Safety and Productivity with State-of-the-Art Mining Machines

Mining companies are constantly striving to improve safety and productivity in their operations, and one way they are achieving this is through the use of state-of-the-art mining machines. These advanced machines are equipped with the latest technology and safety features to protect workers and optimize production.

For example, autonomous haulage systems (AHS) are being increasingly used in mining operations to enhance safety and productivity. These self-driving trucks are designed to navigate through mining sites, avoiding obstacles and reducing the risk of accidents. They also help to improve productivity by operating continuously and efficiently, without the need for driver breaks.

In addition, advanced drilling and blasting machines are being employed to increase the precision and efficiency of mining processes. These machines are equipped with smart controls and monitoring systems that enable operators to accurately position and execute drilling and blasting operations, minimizing the risk of accidents and maximizing productivity.

Furthermore, mining companies are investing in remote-controlled and automated equipment for activities such as rock drilling, excavation, and material handling. These machines allow operators to control and monitor mining operations from a safe distance, reducing the exposure to hazardous conditions and improving overall efficiency.

Overall, the use of state-of-the-art mining machines is helping to transform the industry by making operations safer and more productive. As technology continues to advance, mining companies are likely to adopt even more advanced machines to further enhance safety and productivity in their operations.

The Role of Artificial Intelligence in Modern Gold Extraction Processes

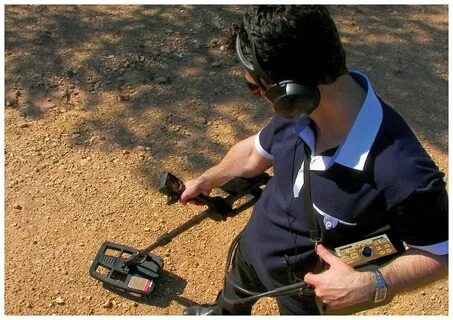

See also: purchase metal detector

The role of artificial intelligence in modern gold extraction processes is significant. AI technology is being increasingly used in the mining industry to optimize and improve various aspects of the extraction process. One of the key applications of AI in gold extraction is in the area of exploration and drilling. By using AI algorithms and big data analysis, mining companies are able to identify potential gold deposits more accurately and efficiently.

In addition, AI is also being utilized in the actual extraction process itself. By employing AI-powered systems for monitoring and controlling the various stages of the extraction process, mining companies are able to maximize productivity, minimize downtime, and improve overall operational efficiency. This can lead to significant cost savings and increased gold yield.

Furthermore, AI technology is also playing a crucial role in the area of environmental sustainability in gold mining. By using AI-powered systems for monitoring and management of environmental impacts, mining companies are able to reduce their environmental footprint and ensure compliance with regulations.

Overall, the integration of artificial intelligence in modern gold extraction processes is revolutionizing the industry, leading to more efficient, sustainable, and cost-effective mining operations.

Adapting to Environmental Challenges: Green Technology in Gold Mining

Adapting to Environmental Challenges: Green Technology in Gold Mining refers to the use of environmentally friendly practices and technologies in the gold mining industry. This includes techniques for reducing the environmental impact of mining activities, such as the use of renewable energy sources, water conservation measures, and the implementation of responsible waste management practices. Green technology in gold mining aims to minimize the ecological footprint of mining operations, protect local ecosystems, and promote sustainable development in the industry. This may involve the adoption of innovative technologies and processes, as well as the implementation of strict environmental regulations and standards. Overall, the goal is to balance gold extraction with environmental protection and conservation.

Unleashing the Power of Drones for Gold Exploration and Surveying

Unleashing the Power of Drones for Gold Exploration and Surveying involves using unmanned aerial vehicles equipped with advanced sensing technology to survey potential gold mining sites, conduct topographic mapping, and collect geological data. Drones can cover large areas quickly and provide high-resolution imagery, allowing for more efficient and cost-effective exploration. This technology also reduces the need for ground-based surveying and minimizes environmental impact. Overall, leveraging drones for gold exploration and surveying can lead to more accurate and informed decision-making in the mining industry.

Optimizing Resources: The Impact of Advanced Machinery on Gold Production

Optimizing resources in gold production can lead to increased efficiency and production output. Advanced machinery allows for more precise and rapid extraction processes, reducing time and labor costs. It also enables mining companies to access lower-grade ores that were previously uneconomical to extract, expanding the potential reserves and ultimately increasing overall gold production. Furthermore, advanced machinery can also improve worker safety by automating hazardous tasks and minimizing human involvement in dangerous environments. Overall, the impact of advanced machinery on gold production can be substantial, leading to higher yields and improved operational efficiency for mining companies.